Advantages and Disadvantages of Plate Heat Exchanger

The Plate Evaporators are also known as the gasketed plate and frame evaporators. Advantages disadvantages of plate heat exchangers.

Advantages And Disadvantages Of A Plate Heat Exchanger Stoll

There are various types of proximity sensors out there in the market but one can say this device often performs its object presence detection task by emitting an electromagnetic field or a beam of electromagnetic radiation infrared for instance and.

. Pressure drop delta PΔP is less than a plate heat exchanger. This facilitates the transfer of heat and greatly increases the speed of the. Cheap compared to plate heat exchangers.

11 Heat Transfer Equipment. A well engineered flat plate collector is delivers heat at a relatively low cost for a long duration. They are widely used in space heating refrigeration air conditioning power stations chemical plants petrochemical plants.

The coolant is enabled either by adding heat to cold oil or draw heat from excessive hot oil. SWEP and Alfa Laval brazed plate heat exchangers. The flat plat collectors is basically a heat exchanger which transfer the radiant.

It consists of a series of closely spaced parallel plates with fins held in between. Advanced heat exchanger development for molten salts. And unlike shell and.

Advantages and Disadvantages of Shell and Tube Heat Exchangers. Plate Heat Exchanger Advantages. Download Free PDF View PDF.

There are four main types of PHE. It also has fins attached over the primary heat transfer surface so as to increase the heat transfer area. Suitable for higher pressures and temperatures compared to plate heat exchangers.

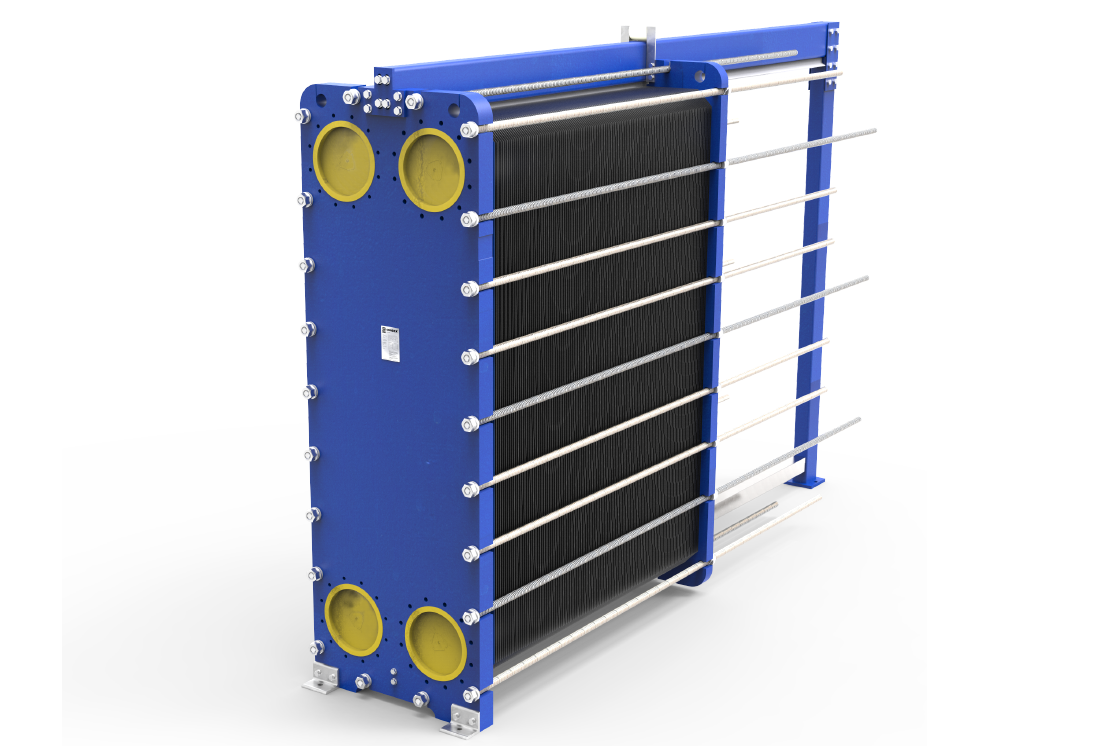

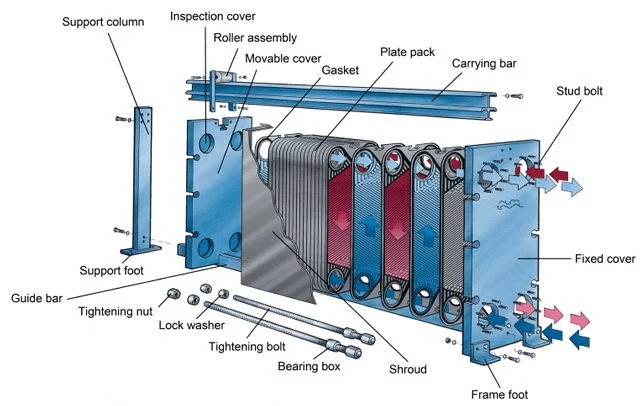

The major advantages of. Plate Evaporators consist of a plate and frame heat exchanger and are mainly used in the food and beverage industry. A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluidsThis has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates.

These plates are supported in a press between a terminal block in each heating and cooling sections. Heat recovery is a method which is used to reduce the heating and cooling demands of buildings. A plate type heat exchanger as illustrated in Figure 2 consists of plates instead of tubes to separate the hot and cold fluids.

Download Free PDF View PDF. We sell a very wide range of compact conventional heat exchangers at low pricesBrazed plate heat exchangers are extremely efficient for heat exchange. Generation IV Reactors Integrated Materials Technology Program Plan.

There are numerous advantages associated with plate heat exchangers. The plate-and-frame or gasketed plate heat exchanger essentially consists of a pack of thin rectangular plates sealed around the edges by gaskets. A steam condenser is a mechanical device employed to condense exhaust steam of the turbine into the water.

Because each of the plates has a very large surface area the plates provide each of the fluids with an extremely large heat transfer area. Gasketed brazed welded and semi-welded. The heat moves from a hot to a cold medium through stainless steel plates.

A steam condenser is a closed vessel-type heat exchanger applied to convert low-pressure exhaust steam from the turbine to water. The Plate Heat Exchanger PHE also called Paraflow is commonly used in the HTST system. They have some unique advantages over some of the more complicated heat exchanger designs as well as some important disadvantages so this article will show buyers.

In either case flat plate construction is the simplest and most compact. Construction and working of Plate type heat exchanger. The hot and cold fluids alternate between each of the plates.

The double pipe heat exchanger is one of the easiest designs to fabricate add on to and repair thanks to its simple design. 2014 Guiqiu Zheng Piyush Sabharwall. Heating water heating DHW heating drinking water heating separation exchanger biogas stations.

Heat recovery ventilation HRV also known as mechanical ventilation heat recovery MVHR is an energy recovery ventilation system which works between two sources at different temperatures. This improves the effectiveness of the. Relatively simple design and easy to maintain.

A proximity sensor is a sensor able to detect the presence of nearby objects without any physical contact. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. Baffles direct the flow of fluid between plates.

By recovering the residual heat in the exhaust gas the fresh air. The flat plate collectors forms the heat of any solar energy collection system designed for operation in the low temperature range from ambient to 60 or the medium temperature form ambient to 100. In these types of oil coolers the coolant passes through a heat exchanger element of some parts.

Its plates may be used for heating cooling and regeneration. As a waterwater exchanger ie. The plates separate the two fluids which flow through passages alternately formed between the plates.

2008 Timothy Burchell. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. Replacing and cleaning of the plates is a simple task because the plate stack can be opened easily.

Plate heat exchangers weigh less require less space and are more efficient compared to other heat exchanger designs of the same size. Focus on Very High Temperature Reactor Materials. A heat exchanger is a system used to transfer heat between a source and a working fluidHeat exchangers are used in both cooling and heating processes.

A counterflow unit has a higher effectiveness than a cross-flow unit of the same area although the simpler manifolding of the cross-flow unit may give it a price advantage which offsets its lower effectiveness. The central component of the system is the heat exchanger. Is a small radiator that enables the engine oil to be cooled directly from an ambient air from the cooling fans.

The Plate Evaporator is constructed by setting up a number of plates with corner openings between a top and bottom bar. The PHE is a compact easily cleaned unit.

Maintaining A Plate Heat Exchanger 2002 03 01 Process Heating

Advantages And Disadvantages Of Shell And Tube And Plate Type Heat Exchangers Cold Drawn Seamless Tube

No comments for "Advantages and Disadvantages of Plate Heat Exchanger"

Post a Comment